86-571-82820723-0

Room 2414, Building 1, Xingyun Didai, Tianhuiyuan, Beigan Jiedao, Xiaoshan District, Hangzhou, Zhejiang, China (Mainland)

2014 Best selling roll forming machine

1. 25m/min speed

2.Only one operator

3.Top quality

4.Competitive price

![]()

2014 Best selling forming machine

1, We do Best, About Machine

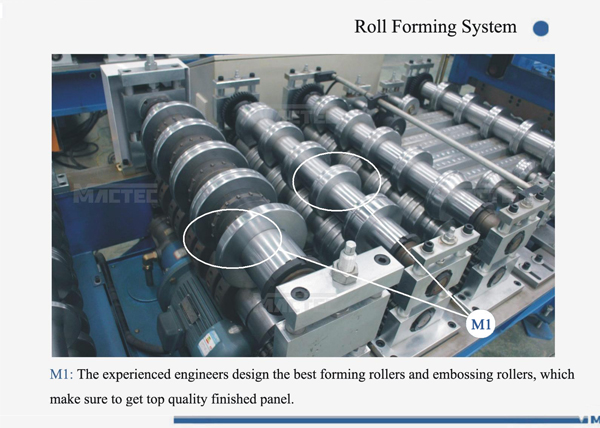

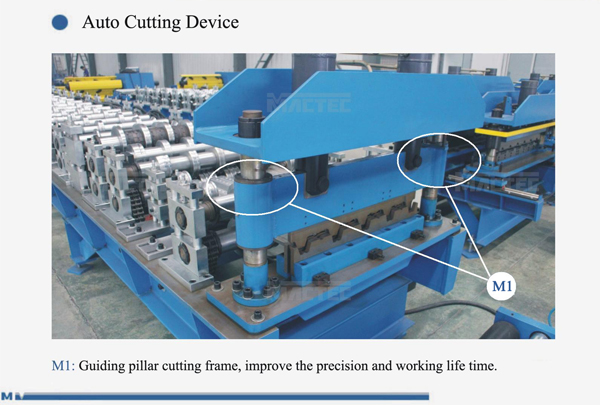

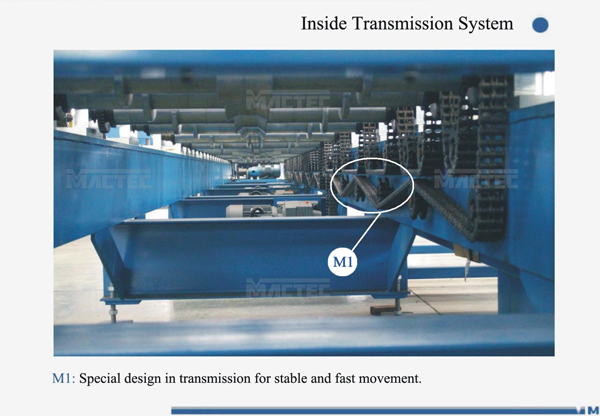

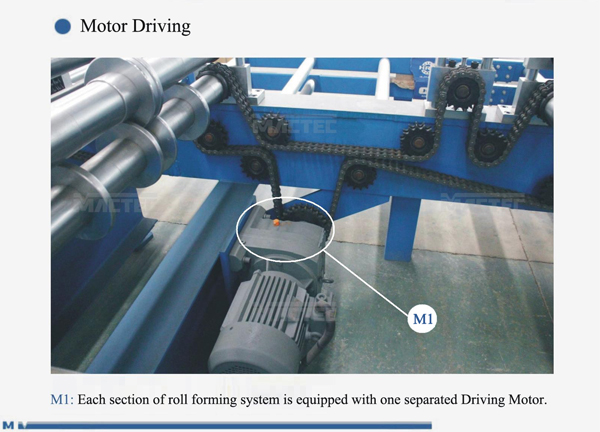

1). To produce the best Roll forming machine, MACTEC is taking EUROPEAN quality standard;

2). Choose the best material and components, and adopting our 15+ years experience;

3). MACTEC achieves that the machine capacity is double of the competitors;

4). The Roll forming machine forming speed is 25m/min standard;

5). Only 1 worker to operate.

2, We do Detail, Machine Parameters

Product name | Forming machine | |||

NO. | Items | Parameters | Remark | |

1 | Suitable

Material | Type | PPGI / GI/GL |

|

Width | Refer to drawing | Custom | ||

Thickness | 0.40-0.70mm |

| ||

2 | Product Specifications | Length | Any length |

|

Length Tolerance | ±2mm/6m |

| ||

3 | Forming Speed | 25 m/min | Standard machine | |

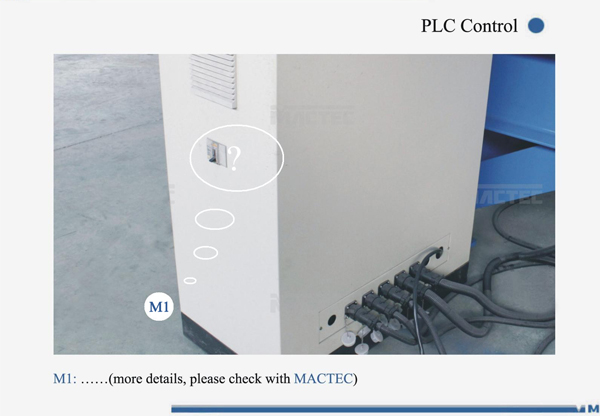

4 | Control System | Mitsubishi/Siemens PLC& transducer | Custom | |

5 | Total Power | About 15KW |

| |

6 | Total Weight | About 11T | Up to final design | |

3, We do Standard, Machine Components

For Corrugated machine, according to our company standard, we will offer you following components as the standard configuration.

4, We do you like,Optional components

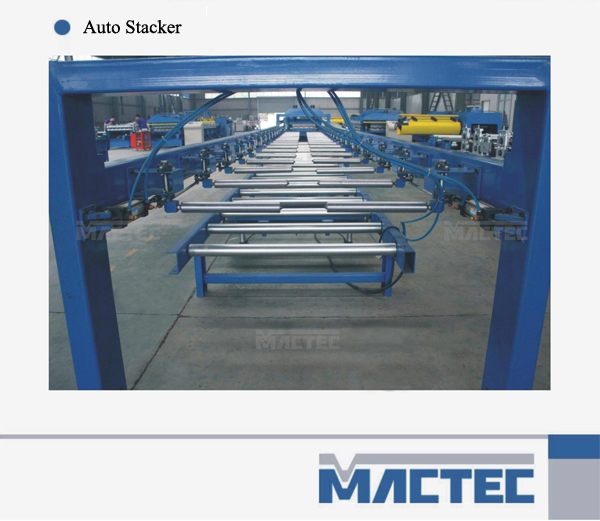

This Roll forming machine has following components can be selected as customer requirements specially.

5, We do Your care, Machine Loading

Because of the long trip and your super trust, we will make sure Roll forming machine can be

appeared in front of you in fully good condition, you will fall in love with it with first glimpse.

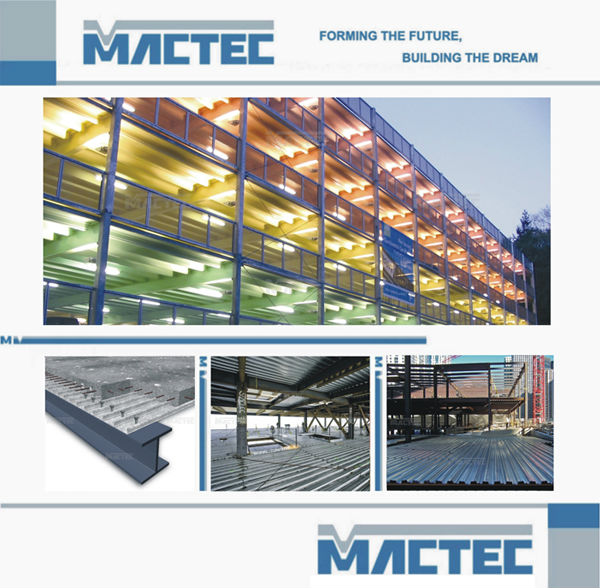

6, We do Your life, Applications

Use our solution, build your beautiful house, enjoy your happy life, have sweet dreams.

7, We do Together, Customers

Meeting you, Growing with you, Enjoying with you.

8, Why MACTEC

1), Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We

need your machines running in order to keep your business running.

2), Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3), Q: How does your factory do regarding quality control?

A: Quality is priority. MACTEC People always attach great importance to quality control from the very

beginning to the end of the production. Every product will be fully assembled and carefully tested before

it's packed for shipment.

4), Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name

components

5), Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. MACTEC is ALIBAB’s Gold

supplier with BV assessment. If you check with ALIBABA, you will see that we have never got any

complaint from our customers.

9, About MACTEC

To be best partner in your great business, MACTEC keeps exploring the best solution for all world market.

The following photos show here we do the works for you.

10, Contact MACTEC

Thanks very much for your time, welcome to contact MACTEC, we are with you within 24 hours.

We want to know following information.

1), What is the exact profile you want to produce?

2), What kind of material you will use, such as steel or aluminium, max coil weight, thickness?

3), What kind of decoiler and stacker you need?